Registrations

We now manually approve all new user accounts due to a large influx of spam bots. Accounts are normally approved within 48 hours.

If you need any help with using this Wiki, please ask here: TalkFord.com Wiki Submission Forum

Difference between revisions of "Headlight Removal – Mk4"

| Line 1: | Line 1: | ||

| − | |||

| − | |||

'''Tools''' needed for headlamp unit removal: | '''Tools''' needed for headlamp unit removal: | ||

Revision as of 05:07, 15 April 2010

Tools needed for headlamp unit removal:

Torx T-30, cross-blade screwdriver, eventually also small flat-blade screwdriver.

Removal

(1) Open the bonnet :)

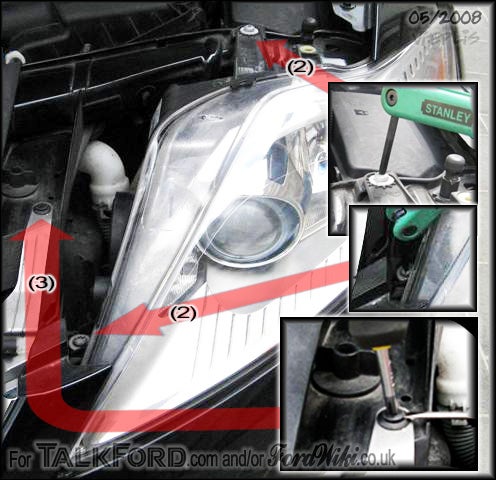

(2) Remove two screws (Torx T-30).

(3) Remove the plastic screw and retainer. If the plastic screw doesn't come out, facilitate it by placing a small flat-blade screwdriver between the screw and the retainer and lifting the screw up.

(4) Pull the corner of the grille and bumper towards the front of the car and

(5) lift the corner of the headlamp and push it as far as possible towards the back of the car.

Aim of steps (4) and (5) is to move the headlamp front corner behind the bumper/grille.

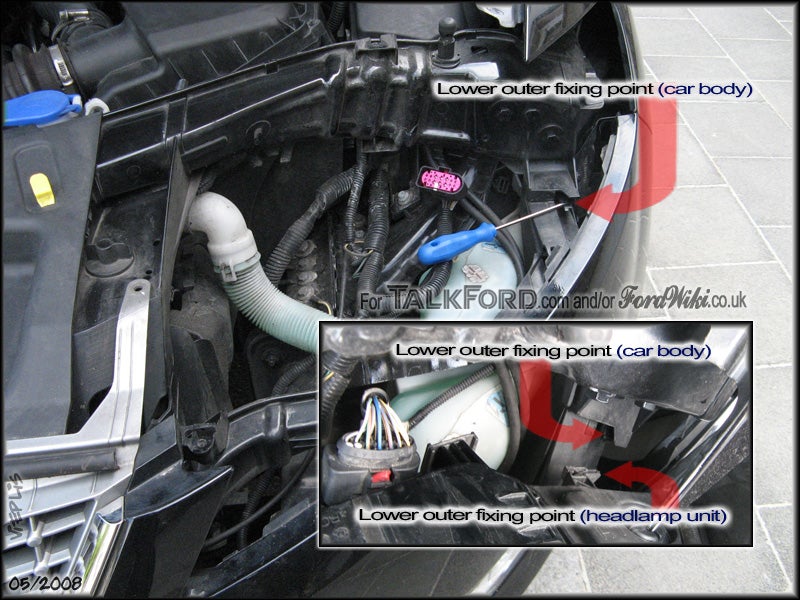

(6) Pull the headlamp towards the centre of the vehicle, behind the grille and bumper, to disengage it from the lower outer fixing point (see subsequent pictures).

(7) Remove the headlamp by moving the headlamp towards the front / to the right.

Steps (6) and (7) are done almost simultaneously.

(8) Unclip the connector, and the headlamp unit is yours.

For location of lower outer fixing point (car body and headlamp unit), see the following pictures.

Some people claim that they have successfully omitted removal step (3).

Fitting

Fitting - in reverse order.

When tightening the two Torx T-30 screws, tighten the front screw first and the rear screw afterwards.

Removal and fitting in winter

If need to change bulb(-s) arises in deep winter, you might be willing to prevent frost-inhibited damage. Plastics may eventually become fragile and/or less flexible due to frost. The "problem areas" might be headlamp unit and/or car body plastics at Torx screw affixing points (stiffness and/or complementary thread's unwillingness to mate with Torx screw thread), along with bumper plastics.

Remove the headlamp when the engine bay is warm, i.e., when it has been running for some time. Mere starting of a cold engine won't provide the effect needed, especially on diesel models, as they heat up slower. Set headlamp switch to "0" prior to removal. Removal and refitting whilst engine is running has no side-effects, except for the following - if the removal was preceded by dipped beam bulb failure, "Low beam bulb fault" warning message won't go away until the next ignition cycle.

As proved in practice on a car with 2.0 petrol engine, removing and fitting of headlamp unit in the midst of a journey at ambient temperature -14° with engine still running didn't surface any problems. By comparison, headlamp unit plastic edges at Torx affixing points were suspiciously stiff whilst fitting at ambient temperature -8° on a "cold" car, therefore final tightening of Torx screws was put aside until engine warms up the engine bay.

Submitted by vieplis

Your Privacy Choices

Your Privacy Choices