Registrations

We now manually approve all new user accounts due to a large influx of spam bots. Accounts are normally approved within 48 hours.

If you need any help with using this Wiki, please ask here: TalkFord.com Wiki Submission Forum

GloveBox Handle Repair

For more information, visit the Ford Mondeo forum on TalkFord.com, the definitive resource site covering all Fords from the present day to the 1970's.

|

Overview Guide | |

| Ford Model: | Mondeo |

|---|---|

| Petrol/Diesel: | ???? |

| Estimated Cost: | ???? |

| Difficulty? | ???? |

| How long does this take? | ???? |

Contents

Overview

The lock body is held in with three size 20 torx screws. The inside of the lock body looks like this

The part which the release lever should go up and down in is in this next pic. Although the lever/handle is made from ABS it is still an obvious weak point, and liable to break.

I decided I could make the lock and hande much stronger, and thus less likely to fail, if I replaced the pivot points/hinges and the catch release lever with stronger material. The diameter of the original Ford pivots was 4mm to I simply replaced them with 4mm steel tent pegs

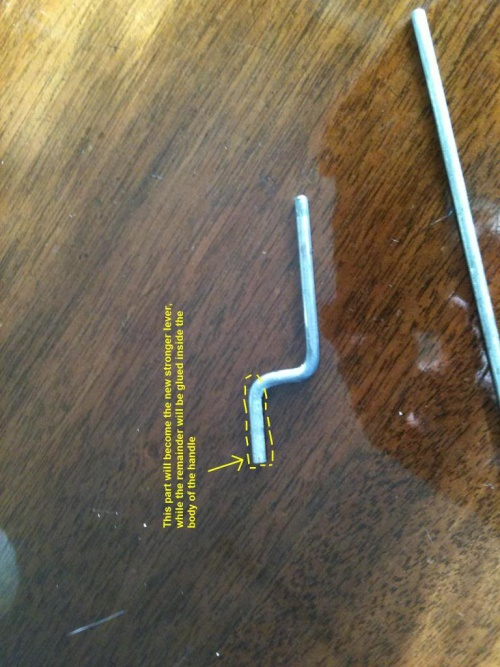

I decided to use one peg to replace the two plastic pivots, and a second peg to replace the catch release lever, but to also glue this bit of peg into the body of the handle to give it maximum strength. It was simply a case of bending the peg to the right shape, and cutting it to length. I also drilled a 4mm hole in the part of the handle where I had filed off the stump of the broken catch, so the new steel handle would be in exactly the same spot.

I used two part epoxy glue to hold the new lever bar in place, as it is very strong and will flow into any gaps quite well. While glueing the new lever into place I temporarily fitted the new steel pivot, to make sure both were in the right place, before the glue set.

I gave the glue time to set, and then fitted the handle into the lock body. The glove box release catch needed to be pushed down before fitting the handle, so that it will operate properly afterwards. The new lever needed a small adjustment just to get it sitting just right in the release catch slot, but this was not a problem really.

Once I was happy with the fit, I trimmed the pivot bar to a better length, and then held it in place with a small blob of epoxy at each end to avoid it slipping out of the lock bodies original holes.

This was a really easy change to make to a quite poorly designed item. The lock will be much stronger now, not to mention it only took forty five minutes to do, including coming up with the idea in the first place.

Alternative Method - Not Yet Fully Broken Handle

PICTURES TO BE ADDED SHORTLY TO THIS ALTERNATIVE FIXING METHOD

If you find yourself like me with my replacement glovebox handle in that it is showing the signs of getting ready to break ( see piccy below ) then the following fix can come in useful

( piccy to come when i find it again on my PC )

Tools / Parts Required

Sperglue Q-Bond or other similar fixing material ( hot melt glue gun etc ) Thin metal strip ( pictured is a metal bar from a laptop screen securing bracket ) Metal Cutters ( Tin Snips etc ) Mole Grips

May need :-

Sand Paper

Method

Remove Handle From The latch Braket.

Cut a suitably sized length of metal bar ( i made the strip long enough to go all the way to the bottom of the inner handle fixture & then to the edge of the damaged bracket )

Now bend the metal strip to 90 degrees where it bends over onto the broken bracket ( best done using a solid item such as a table edge & the mole grips etc to form a nice sharpe bend )

Now put the metal strip into place on the handle & then make sure it fits snugly

Now apply superglue to the broken bracket arm under the metal strip & fix the metal strip into position on the arm/glue using the molegrips & let the glue set suitably.

( piccy )

Once the superglue has set put plenty of Q-Bond or hot melt glue etc into the hole in the handle to fully secure the other end of the metal bar to finish securing repair bar & leave this to set fully ( if using Q-Bond then this is a matter off moments really )

( piccy )

Now test fit the handle back into the latch unit & check for full operation.

If resistence is felt when operating the handle then remove the handle & sand down the area of the latch unit back panel where the repaired arm goes to operate the latch.

* Repeat the last 2 steps as many times as required to get the handle to operate smoothly.

Job done :D

Your Privacy Choices

Your Privacy Choices