Registrations

We now manually approve all new user accounts due to a large influx of spam bots. Accounts are normally approved within 48 hours.

If you need any help with using this Wiki, please ask here: TalkFord.com Wiki Submission Forum

Pistons for the 2.5L and 3.0L Duratec

For more information, visit the Ford Mondeo forum on TalkFord.com, the definitive resource site covering all Fords from the present day to the 1970's.

|

Overview Guide | |

| Ford Model: | Mondeo |

|---|---|

| Petrol/Diesel: | ??? |

| Estimated Cost: | ??? |

| Difficulty? | ??? |

| How long does this take? | ??? |

This page is a direct copy of the information found http://www.rumodded.com/warmonger/pistons/pistons.htm . It has been copied across in the eventuality of the original website going offline, and thus losing this valuable piece of information. Full credit goes to the original contributor. UPDATE - THE ORIGINAL WEBPAGE HAS NOW GONE OFFLINE.

This is some general discussion on the pistons for the Duratec V6 family of engines from 1995-present.

Stock Ford pistons

The pistons used by Ford in these engines are cast hypereutectic aluminum alloy. They are not forged and they are not nearly as strong as forged pistons. However, they do have some very distinct advantages.

1) Light-weight

2) Low coefficient of thermal expansion

3) Molybdenum coated skirts

4) Low variation

These advantages come from the properties of the hypereutectic alloy used. The term hypereutectic comes from metallurgy and in the case of these pistons it refers to compositions of the alloy of aluminum and silicon. It is graphically portrayed on a binary phase diagram as any composition of two metals whose plotted point falls to the right of the eutectic line. More simply put, if an alloy of Al-Si is hypereutectic then it means that there is more silicon mixed with the aluminum than can be easily dissolved once it solidifies. As the molten alloy is cooled the silicon begins to come out of solution and form precipitates, or little pieces of silicon crystals spread throughout the aluminum matrix because they can't stay dissolved. These little "islands" of silicon that are spread throughout the aluminum matrix greatly harden the metal create a phenomenon known as precipitation hardening. They also cause a change in thermal properties resulting in a lower coefficient of thermal expansion and heat transfer.

Other reasons for alloying silicon with aluminum pertain to the casting methods used to make the pistons. Since the pistons are made to precise tolerances, the manufacturer needs to pour the aluminum into the mold and have them solidify exactly the same way every time. An alloy with a composition near its eutectic will solidify almost all at once. An alloy that has a composition far from its eutectic will solidify at different rates with regard to the parts of each of the alloying elements. The precipitations of a hypereutectic alloy of Al-Si are an example of this but are tightly controlled to gain the desired properties and maintain low variation from one cast piston to another.

The thermal properties associated with this type of piston allow it to be installed into cylinder blocks with much tighter piston-bore clearances than forged pistons or other older piston designs. These tighter clearances are allowed because of the small coefficient of thermal expansion as compared to that of forged alloys or pure Al parts. The tighter clearances keep more of the combustion gasses in the combustion chamber so there is less blow-by into the crankcase. This reduces contamination of the oil and increases power. It also makes the pistons much quieter as they move in the bores and reduces overall engine noise not to mention lower exhaust emissions.

The molybdenum coating on the skirts is just designed to reduce scuffing of the cylinder walls from friction since the clearances are so much tighter.

The main disadvantage of the cast piston is that it is not nearly as strong as a forged piston. This is because the metallic properties are not the same all the way through the piston. Castings can develop voids, or open spaces as the liquid metal cools and contracts. These voids are stress concentrators and make the part weaker when they develop. The properties of the metal are not the same throughout the material because the rate of cooling changes as the metal cools and affects the rate and direction of solidification.

Forged Pistons

Forged pistons have the advantage over cast pistons in strength. A forged metal is a metal that is mechanically worked by force into a uniform lump and tends to become harder from the process. The forged metal is then machined into the desired shape of the part. If you sliced open a forged part and examined the cross section you would find that the material usually is very uniform in density and mechanical properties throughout the part. Forged pistons are generally made of hypoeutectic alloys of Al-Si and are not as hard or brittle as the above mentioned hypereutectic parts. This helps to improve the machinability and as a by product helps the piston absorb a little more abuse during operation if the load on the piston exceeds its yield strength. Yield strength is an important term but I'm not going to cover it here. Suffice it to say that a hardened material cracks close to its yield strength because it has less tendency to bend. A softer material will bend back and forth before it breaks. For the purposes of our discussion, a hypereutectic piston is harder and will tend to crack if its max load is exceeded whereas a forged piston will give a little and distort if its max load is exceeded.

There are only a few disadvantages to forged pistons but they are worth mentioning. The first is cost and availability. Because the parts are machined out of a lump of forged metal they cost as much as 6-8 times what a cast piston would cost! That isn't cheap, a set of six forged pistons for a Duratec is running $650-800 right now. Cast replacement pistons are running roughly $20 each now if you shop for deals. Another disadvantage to most forged pistons is the higher coefficient of thermal expansion. They have to be capable of running the tightest clearances when the combustion chamber is at its hottest, and that means that for anything besides full throttle like normal cruise and cool temperatures they are going to have increased piston to bore clearances. This increases combustion chamber blow-by when the pistons are being run at normal and cold start engine temps as well as noise and ultimately increases tailpipe exhaust emissions. Some of these factors can be mitigated by the types of alloy chosen for the forgings, but in general hold true. The last disadvantage is increased weight due to the higher density. This isn't a big deal but it would be better to have less rotational mass rather than more.

Specific Duratec related issues:

I did quite a bit of research on the different pistons found in the various years of 3.0L and 2.5L motors and found that there were several design changes from 1999 to 2001. The bottom line is that the 1999 and earlier pistons had a weaker ring land design and when subject to very high combustion chamber pressure they will crack. The mid year 2000 pistons had a revision in design that relocates the ring lands and strengthens the piston. This allows us to run boost a little bit safer on 2000+ pistons than we could on the older models.

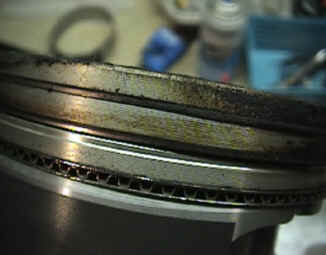

Failed Pre-2000 Pistons:

Comparison of the Ring Lands between pre and post 2000 pistons:

1998- early 99 3.0L piston 2000 2.5L piston 2001 3.0L piston

Look carefully at the three pistons above. The '98 piston on the left has the same space between the upper and lower compression rings as the two later model pistons on the right. The upper compression ring is located lower down the piston, or further away from the piston crown than it is in the later model pistons. There you can see the the lower compression ring is much closer to the oil control ring in the early piston whereas in the later pistons the distance is twice as thick. In the '00 and '01 pistons on the right you can see that the two compression rings were just repositioned a bit higher up on the piston thereby increasing the metal thickness between the oil ring and the lower compression ring and reducing the thickness between the upper compression ring and the piston crown. This minor design change has a lot of consequences. It allows less room between the piston and the bore for hydrocarbons to be trapped and at the same time doubles the thickness and strength of the aluminum supporting the lower compression ring. In the first row of pictures you will see how the ring lands broke out due to the high pressure. It is my belief that the thinner metal below the lower compression ring on the '98-99 piston broke first under load and the resulting lack of support allowed the ring land above it to also break.

I proposed this theory a while back and I got a mixed response with probably half the people claiming that the piston cracks are caused by detonation from running lean and/or too much timing. In the case of my engine it was not detonation or timing. Just for added thought, I have a picture courtesy of Buckshot below that shows what happened to a stock piston from a lean mixture and detonation. If you compare with those above you'll see they are nothing alike. The crown of the piston will show melt spots, distortion and pitting after detonation.

Your Privacy Choices

Your Privacy Choices